Humans are tool makers—it’s one of the behaviors that separates us from the animal kingdom. Sure, chimpanzees use sticks to pull ants from their hives. And some crows fashion crude instruments for hooking grubs. But the diversity and sophistication of human tools puts us in a league of our own.

As they grow more complicated, our tools become machines—intricate systems engineered to achieve an action quickly, consistently, and affordably. After centuries of practice, modern human machines are more numerous than we could ever imagine. It follows that servicing those machines takes an expert hand and deep experience.

What Types of Machines Benefit From Preventive Maintenance, Laser Alignment, & Balancing?

Since 1995, Cornerstone Mechanical Services, Inc., has worked on just about every machine imaginable. With nearly three decades of experience under our belts, we’re ready to balance, align, or maintain nearly all of your vital equipment.

To schedule corrective, predictive, or preventive maintenance, give us a call today at (214) 570-9498 or contact us online. In the meantime, here are the machines we work with most frequently.

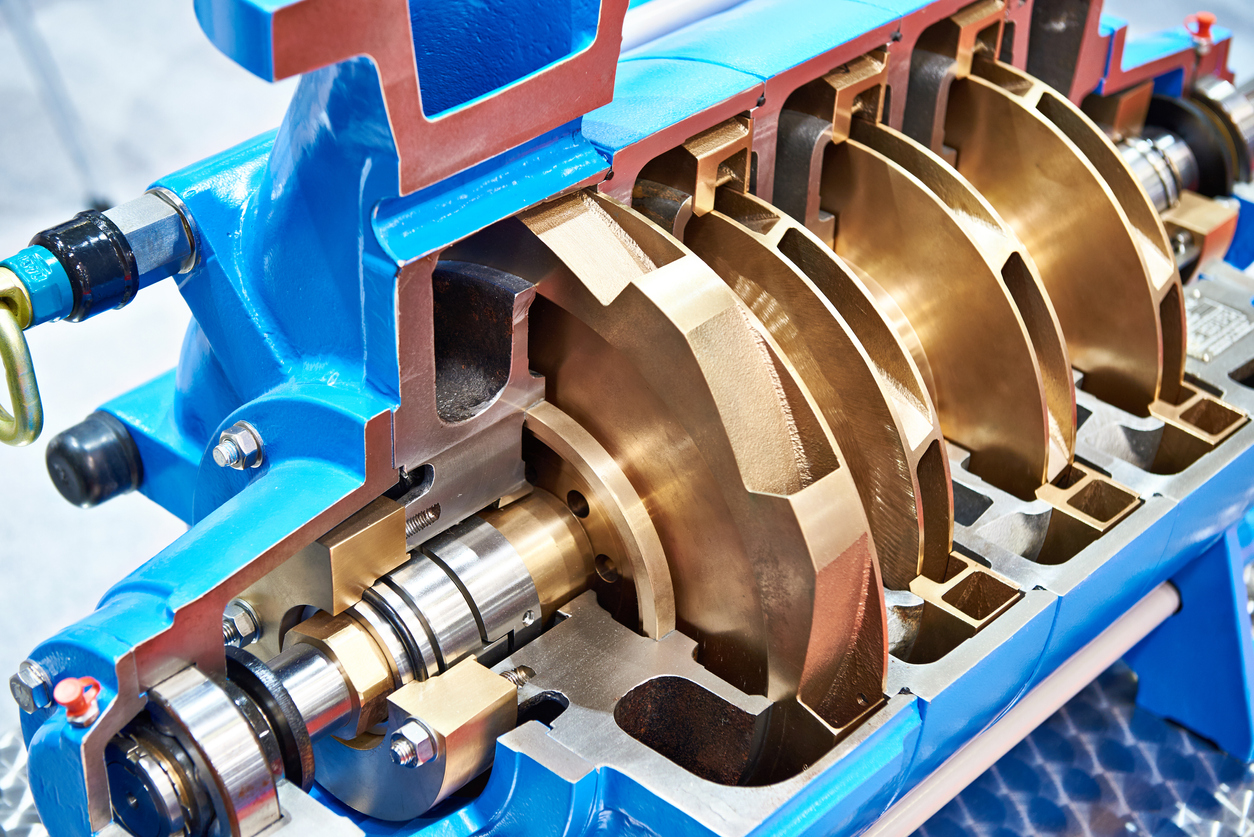

Centrifugal Pumps

As with all forms of centrifugal machinery, vibrations are a contributing factor to malfunctions in centrifugal pumps. Misalignment can cause serious vibrations, sabotaging performance and increasing wear and tear.

Additionally, centrifugal pumps can heat up quickly when one component underperforms. This can shorten the lifespan of both individual parts and the unit as a whole.

Centrifugal Blowers

Here again, centrifugal blowers are highly susceptible to damaging vibrations. Misalignments in the shaft or imbalanced rotors can quickly increase heat, wobble, and the need for new parts.

For centrifugal machinery of all types, it’s important to establish and maintain a preventive maintenance program. Otherwise, you risk expensive emergency repairs and even work stoppages over issues that could have been caught and corrected.

Exhaust Fans

For both machine performance and human safety, exhaust fans should never be neglected. An imbalanced fan, misaligned shaft, and numerous other issues could make proper ventilation impossible.

Naturally, if the exhaust fan struggles to force out fumes, those fumes can back up into your machine or your place of work. This also increases the operating temperature, contributing to a knock-on effect that could sink your machine in no time flat.

Dust Collectors

Like any other filtering device, dust collectors need to be monitored and replaced before they contribute to major issues. The right preventive maintenance program will include any and all replacement parts, a full system diagnostic, and a follow-up performance check to ensure that everything’s working as it should.

Components that remove fumes, particles, or other matter from a limited system deserve our attention. When everything’s flowing, machines and the humans that operate them can work seamlessly and safely.

Cooling Towers

Temperature regulation is no joke—both in our structures and our equipment. Our machines may be among the toughest, most highly engineered examples of their kind, but they can quickly malfunction without the correct operating temperature.

Cooling towers suffer frequently from scaling, corrosion, particle buildup, and even organic deposits that grow over time. Frequent inspections and maintenance can keep temperatures (and business days) workable.

Make-Up Air Units

Maintaining required machinery is a part of doing (and staying in) business. Make-up air units are certainly no exception. For safety and regulatory reasons, regular maintenance on make-up air units is a literal must.

Make-up air units are susceptible to numerous environmental and mechanical hardships. Negative pressure, backdrafting, and higher energy bills are just some of the dangerous and expensive issues make-up air units face when they’re not regularly maintained.

Then, of course, there are the regulatory punishments you may incur if your make-up air unit fails or underperforms. Work stoppages are only the tip of the iceberg when neglecting performance here.

Maintain, Balance, & Align All Your Vital Machinery

Since 1995, Cornerstone Mechanical has kept businesses of every stripe humming right along in the Dallas-Fort Worth Metro area. The first and best defense against work stoppages and expensive repair bills is a dedicated maintenance program.

At Cornerstone, we can help you establish a maintenance routine suitable for all your vital equipment. With preventive, corrective, and predictive maintenance services, we prevent emergencies before they ever occur.

Additionally, our laser alignment, dynamic balancing, and conditions monitoring services ensure peak performance throughout the fiscal year. So, how can we help you today? Give us a call at (214) 570-9498 or contact us online to let us know!

From Centrifugal Pumps to Cooling Towers, We’ve Got You Covered!

Don’t see your equipment in the list above? No worries! With the latest technology, decades of experience, and highly-trained technicians, we can work on just about anything! Keep your doors open, your machines humming, and revenue flowing with Cornerstone Mechanical’s suite of maintenance services. Call us today and let us know how we can help your equipment.