Grouting & Commissioning FAQs – Answering Your Questions

Heavy machinery usually comes with an equally hefty price tag. But purchasing, installing, and maintaining your machinery all represent significant investments into the continued operation and success of your business.

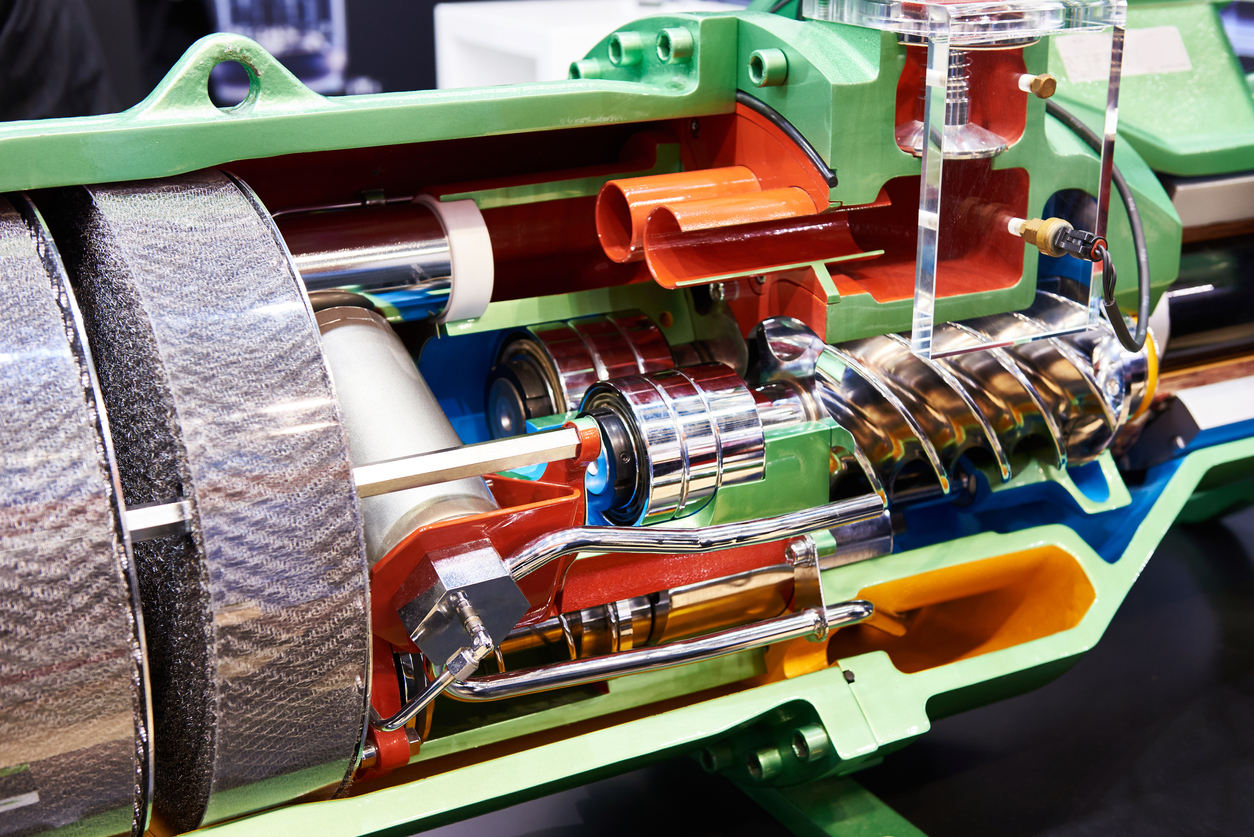

Heavy machinery moves, breathes, and ages in different ways depending on its function. For centrifugal machinery, carelessness during the installation process can accelerate wear, limiting the lifespan of your equipment while also increasing the frequency and cost of repairs.

Thankfully, Cornerstone Mechanical Services, Inc., offers expert installation, grouting, and commissioning services to get your heavy machinery started on solid footing. But how can Cornerstone Mechanical help? Let’s take a look.

What is grouting & commissioning?

Grouting & commissioning is the process of securing a machine’s footing to eliminate damaging movement during operation. The process typically begins by using cutting-edge technology and metrics to determine if a machine’s mounting locations are coplanar.

Depending on how well your machinery was installed the first time around, specialists may buttress and realign your equipment using epoxy grout or other methods to ultimately extend your machine’s lifespan and continued health.

Why is grouting & commissioning necessary?

All the energy created by the operation of your machine transfers to its mounts. Depending on how your machine was installed, its mounts may be more or less sturdy. For centrifugal machinery especially, constant usage can create gaps in the footing which may lead to wobble and accelerated wear across the board.

Grouting and commissioning can extend the lifespan of your machine by reducing the potential for wobble or imbalances during operation.

How can grouting & commissioning save me time and money?

Generally speaking, we expect our heavy machinery to stay put where it’s installed. But over time, machines tend to wobble, vibrate, or misalign. This is especially true of centrifugal machinery relying on high-speed rotation.

Your machine was not designed to operate over years and years with misalignments, wobbles, and vibrations. Left uncorrected, minor movements can cause excessive wear and tear, leading to more frequent (and more costly) repairs, or even compromising the functionality of your machine altogether.

By better securing your machinery and maintaining coplanar mounting all around, your machine can run harder, longer, and more affordably, saving you both time and money.

How can I prevent wobbles/misalignments during installation?

The best way to prevent wobbles and misalignments from developing is to hire a company with extensive expertise for the installation process. Cornerstone Mechanical understands how machines migrate over time and how to prevent that migration before it starts.

Cornerstone Mechanical can get your working relationship with a machine off on the right foot by securing its feet as firmly as possible. In the hands of less experienced installers, your expensive investment may require further injections of cash and downtime to reinstall, repair, or correct. By choosing your installer wisely the first time around, you could save hundreds of thousands of dollars in both the short and long terms.

Less Wobble, More Profit

In successful industries, we want our products to move, not our heavy machinery. To secure your investment in your machine (and your business as a whole) everything needs to run longer, better, and without costly downtime or sky high repair bills.

At Cornerstone Mechanical, we speak, breathe, and dream about heavy machinery. From the installation process onward, we’re here to keep your business running. Through dynamic balancing, laser alignment, and our preventive/predictive/corrective maintenance programs, you can rest easy knowing that you’ve done everything possible to give your machines and your business the best chance at long term success.

Getting off on the right foot makes all the difference!

You wouldn’t spend a ton of money on a dinner table that wobbles. Heavy machinery is certainly no different. When installing your machine, or deciding on a long term maintenance program, trust the folks who’ve seen it all. Cornerstone Mechanical knows what machines need to stay happy and healthy so that your business stays the same. To learn more, contact us today or call (214) 570-9498!