Reliable

Predictive Maintenance

The best emergencies are the ones that never happen. With Cornerstone Mechanical’s industrial predictive maintenance services and cutting-edge technologies, you can identify problem areas and faulty pieces of rotating equipment long before they reach a critical state of failure. The more you know about your machinery, the further into the future you can see.

The efficiency and asset reliability of your production hinges on the reliable operation of your equipment. Our specialization lies in mitigating unexpected and costly shutdowns in your production systems through our industrial predictive maintenance services, including vibration and monitoring analysis and infrared thermography. Through these programs, we can proactively pinpoint issues before they escalate into failures, affording you the opportunity to procure necessary parts and schedule maintenance at your convenience.

Want to further explore our industrial predictive maintenance service offerings?

A robust predictive maintenance program goes beyond resting on its laurels. For optimal outcomes, these predictive model programs encompass a myriad of methods and metrics to ensure that your equipment consistently operates at peak performance levels. In the realm of predictive maintenance services, Cornerstone Mechanical stands out by incorporating infrared thermography and oil analysis into our suite of predictive maintenance program options.

Given the inherent variability in maintenance costs among plants, a one-size-fits-all approach to industrial predictive maintenance services is impractical. At Cornerstone, we pride ourselves on crafting bespoke predictive maintenance programs tailored to suit the unique needs of your facility.

In the realm of predictive maintenance analytics, our commitment to customers extends beyond mere formulas. We recognize that each facility is distinct, prompting us to design custom predictive maintenance programs that align seamlessly with your requirements and operational nuances.

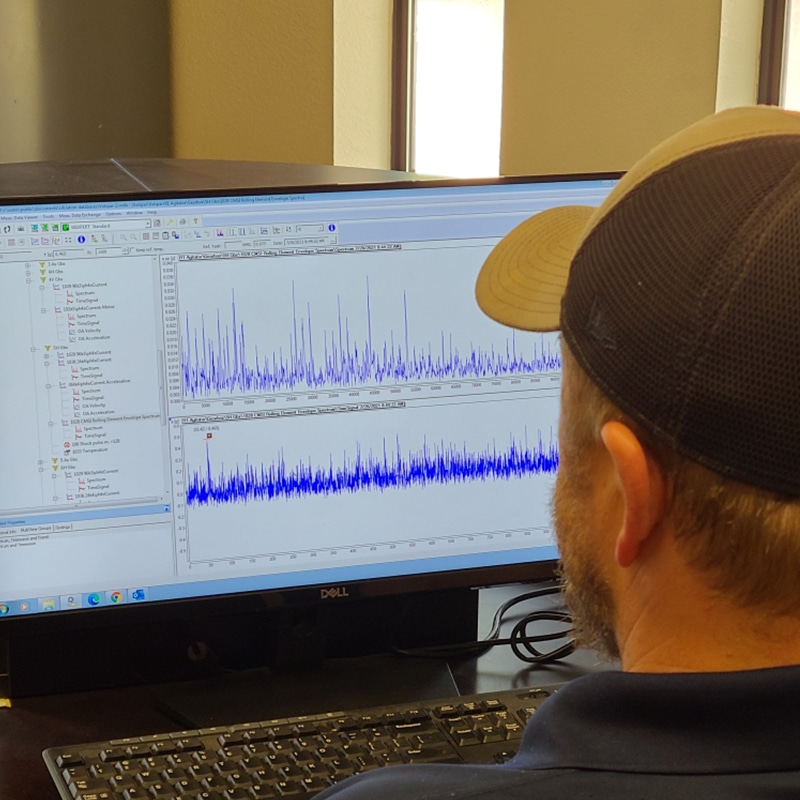

Whether it’s off-route vibration testing or in-depth analysis software solutions for equipment exhibiting elusive problems, our team is equipped to provide comprehensive solutions. We extend both single-speed and variable-speed vibration testing, ensuring a thorough examination of your equipment’s health.

In essence, our suite of predictive maintenance services transcends the conventional, encompassing innovative methodologies and a commitment to meticulous maintenance planning. Trust Cornerstone Mechanical to be your reliable partner in sustaining your equipment performance and the optimal functionality of your equipment.