In industrial operations, precision isn’t optional—it’s essential. Even the smallest misalignment or imbalance can rack up costly repairs, excessive downtime and accelerated wear and tear on your rotating equipment.

That’s where precision equipment alignment services and dynamic balancing services come in.

The Importance of Proper Balancing in Rotating Equipment

Proper balancing is essential for maintaining the integrity and longevity of rotating equipment. Equipment imbalance occurs when rotating components, such as fans, pumps or turbines, have uneven weight distribution. This causes excessive vibrations that can stress bearings, seals and other critical parts.

Lack of proper balancing in rotating equipment can lead to:

- Excessive wear and tear

- Increased likelihood of mechanical failure

- Costly repairs

- Unscheduled downtime

By addressing imbalances, industrial operators can:

- Reduce maintenance costs

- Increase system efficiency

- Improve safety conditions for workers

- Reduce energy consumption and, in turn, overheating

The Importance of Laser Shaft Alignment Services for Rotating Equipment

Laser beam alignment services offer unmatched accuracy and efficiency in correcting misalignments in industrial machinery. Misalignment in rotating equipment can be caused by improper mounting, thermal expansion over time, excessive loads and more.

Over time, misalignment can lead to:

- Uneven wear on components

- Increased vibration and stress on motors, bearings and shafts

- Costly repairs

- Reduced equipment lifespan

With laser alignment of rotating equipment, minor misalignments are corrected, which:

- Maintains optimal performance

- Lowers maintenance costs

- Improves safety conditions for workers

- Minimizes the risk of unexpected equipment failure or component breakdown

For industries like aviation, where precision is paramount, laser shaft alignment services provide peace of mind that rotating equipment operates within exact tolerances.

Why Dynamic Balancing & Alignment of Rotating Equipment Isn’t A DIY Job

Dynamic balancing and laser alignment of rotating equipment require precision, specialized technology and industry-specific expertise that surpass standard in-house capabilities. Attempting these tasks without the right equipment and experience can lead to inaccurate results, quickly impacting machine performance and safety.

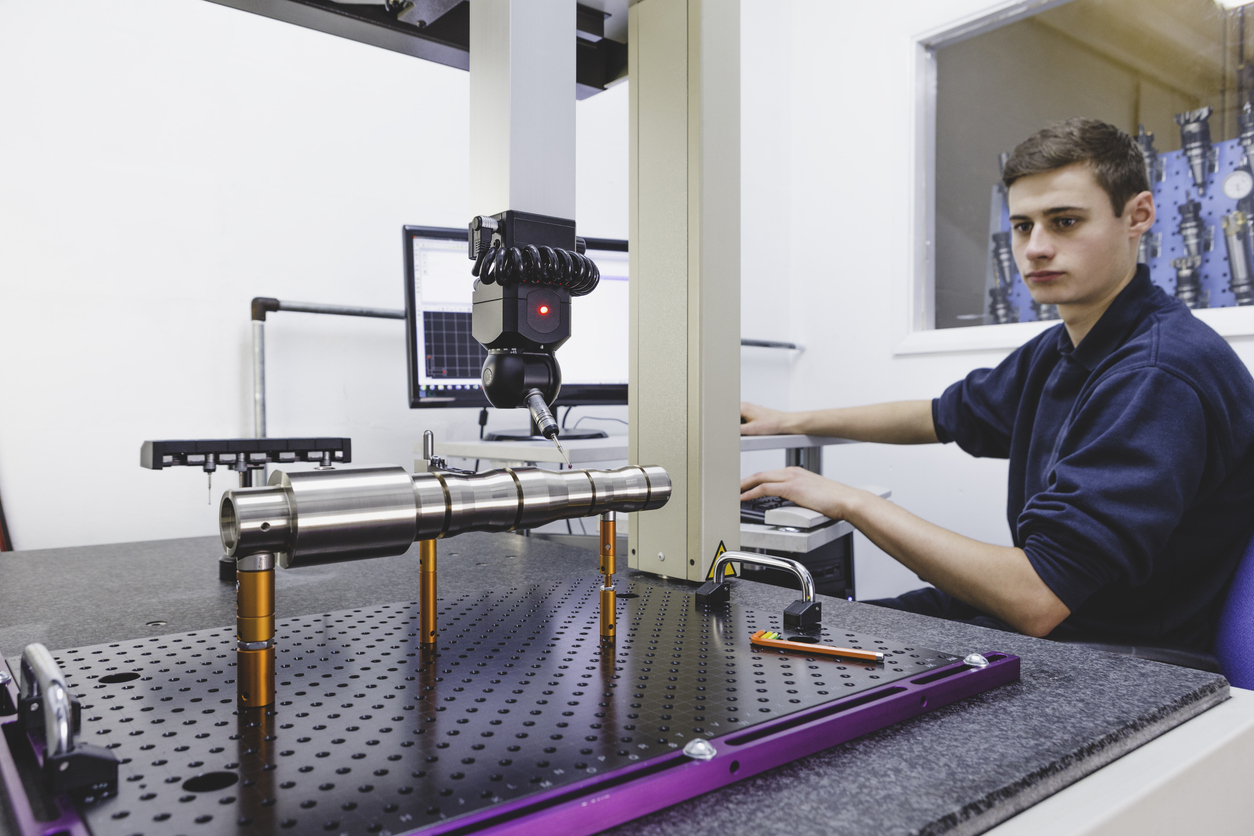

Traditional alignment methods involving manual measurements can be time-consuming and lack precision. Laser alignment of rotating equipment, on the other hand, uses advanced technology to achieve precise alignment in a fraction of the time. At Cornerstone Mechanical, we utilize state-of-the-art laser alignment technology that delivers precise, reliable measurements so machinery functions seamlessly.

In addition to advanced laser alignment technology, our reliability technicians utilize dynamic balancing machines that adjust rotating equipment while it operates. This technology allows our team to make immediate adjustments and correct imbalances in real time to improve machinery efficiency and safety. This capability is particularly advantageous in environments with continuous operations, like food processing or water treatment facilities, where minimizing downtime is crucial.

When your rotating equipment is imbalanced or misaligned, don’t bother with manual measurements or attempting to correct an imbalance by hand. For over 30 years, Cornerstone Mechanical’s reliability technicians have been using top-tier technology to provide high-quality service for our customers in North Texas and beyond.

Give us a call at 214-225-7038 to see how our dynamic balancing services and laser alignment services can optimize your rotating equipment’s performance.