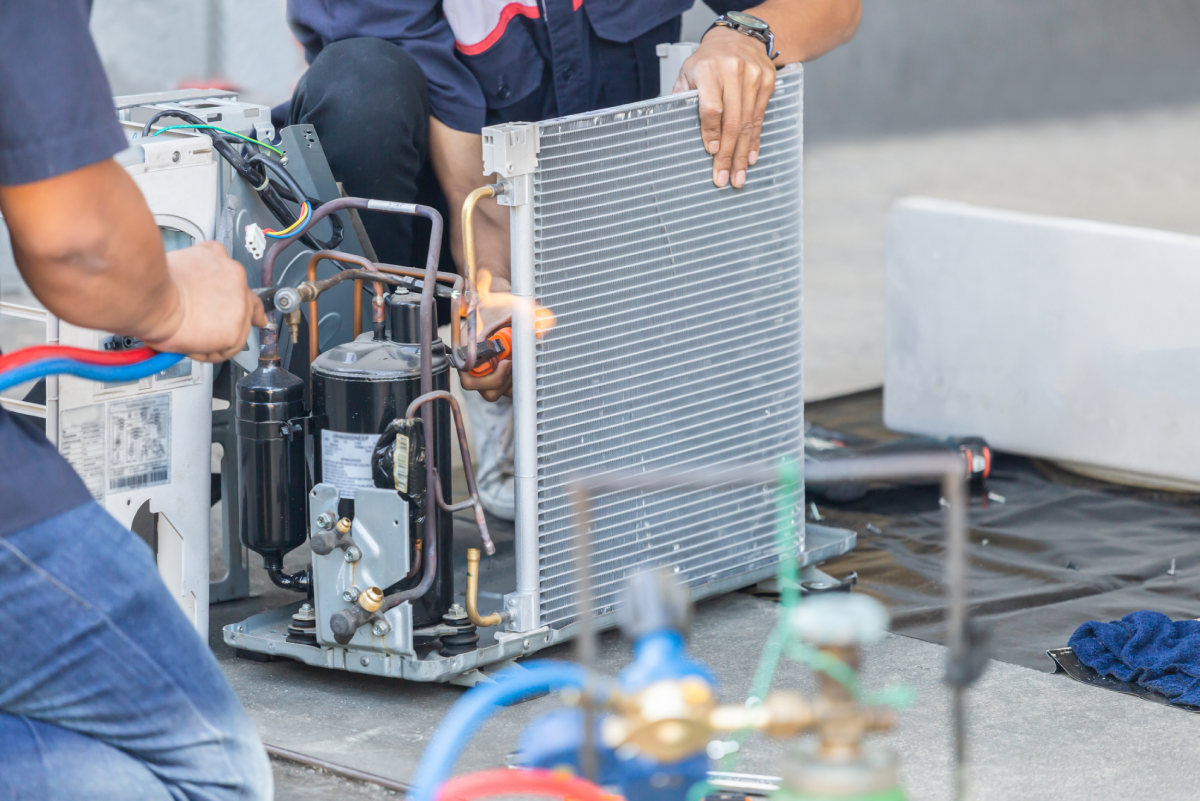

Even the most advanced piece of rotating equipment can fail before it ever goes into operation—not because of a design flaw, but because of a poorly performed installation.

Cornerstone Mechanical Services specializes in supporting your machinery throughout its entire life cycle, and no part of said life cycle is more important than its start. Here’s how Cornerstone Mechanical helps your rotating equipment get off on the right foot.

Why Expert Heavy Machinery Installation Matters

Proper heavy machinery installation is more than just getting your equipment up and running—it’s about ensuring long-term reliability, performance and safety. Poor installation can lead to misalignment, imbalance and excessive vibrations, which can rack up costly downtime and expensive repairs.

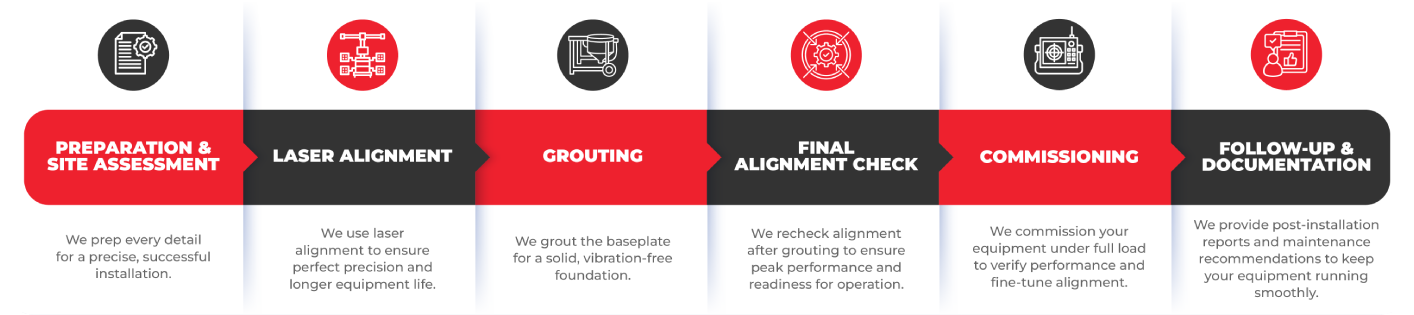

Cornerstone Mechanical’s Proven Machinery Installation Process

With over 30 years in the business, Cornerstone Mechanical Services has our tried-and-true heavy machinery installation process down to a science. Our technicians leave no stone unturned to ensure that your rotating equipment is installed to last.

Step 1: Preparation & Site Assessment

Before our team even arrives at your facility, we ensure that we have the proper tools and equipment we need to make your machinery’s installation a success. Our technicians also meticulously review the manufacturer’s specifications for your piece of rotating equipment to plan proper placement and mounting procedures.

Once arriving onsite, our team conducts a thorough assessment to make sure the installation site is clean, level and free of any debris that could interfere with the installation process. We also check to see if the foundation is level and if it can support the full weight and operating load of your piece of machinery.

Step #2: Laser Alignment

Once we put the baseplate into position, precision alignment is critical. Our technicians perform laser alignment services to ensure that your rotating equipment’s shafts and couplings are perfectly aligned prior to operation.

This crucial step extends your machinery’s operating life by relieving undue stress from couplings, bearings and seals right from the start.

Step #3: Grouting

After alignment, it’s time to secure the baseplate to the concrete foundation through the grouting process. This ensures a sturdy, vibration-free connection by filling any gaps between the two components with epoxy grout or cementitious grout, depending on the piece of rotating equipment.

Step #4: Final Alignment Check

Our technicians understand that even a small deviation can have a major impact on performance, which is why we perform an additional alignment check. Your machinery’s shafts and couplings may become misaligned during the grouting process, so verifying alignment one more time during installation helps ensure your piece of rotating equipment is ready to move on to commissioning and operation.

Step #5: Commissioning

Following installation, our technicians commission your machinery by ensuring it runs well under actual working conditions. Our team monitors your rotating equipment’s vibration levels and alignment while running at full capacity and makes any necessary final adjustments prior to operation.

Step #6: Follow-Up & Documentation

Our service doesn’t end once your machinery is up and running. The Cornerstone team provides detailed reports on the installation process and recommendations for scheduled maintenance to keep your piece of rotating equipment running smoothly.

Benefits of Industrial Machinery Installation Done Right

Partnering with an experienced machine installation team pays off long after the installation process is over. When your machinery installation is done right the first time, it:

- Lowers your long-term maintenance costs

- Extends your equipment’s lifespan

- Improves your machinery’s efficiency and performance

- And more

Whether you need to install a fractional motor-pump set or an 8,000-HP motor-driven centrifugal compressor, the Cornerstone Mechanical team has you covered. Call us at 214-225-7038 to see how our reliability technicians can help you give your rotating equipment the great start it needs.