Is your centrifugal pump vibrating abnormally? Compressor making louder noises than usual? If so, your rotating equipment’s components may be misaligned.

For over 30 years, Cornerstone Mechanical Services has performed laser and optical alignment services on misaligned rotating equipment components to enhance machinery performance and longevity for folks throughout North Texas and beyond.

Keep reading to learn more about laser and optical alignment services, why they’re important and how our team performs them.

What Are Laser Alignment Services?

Laser alignment services use high-precision lasers and other metrology methods, such as optical alignment services, to measure and correct the alignment of various components in pumps, blowers, turbines and other machinery.

Why Are Laser Alignment Services Important?

While not always immediately dangerous, misalignments within your rotating equipment can create strain on its components and produce excessive operational heat. This can eventually lead to safety hazards or total equipment failure. Laser alignment services ensure that your machinery’s components run on the same axis with tight tolerances.

By correcting misalignments within your machinery, laser alignment services ultimately enhance your machinery’s performance and reduce the frequency of costly emergency repairs.

What Kinds of Machinery Benefit from Laser Alignment Services?

Misalignment can affect vital, system-wide machine components such as shafts, couplings, seals, bearings, pumps and more. Cornerstone Mechanical offers the following laser alignment services:

Laser Alignment Procedure for Rotating Equipment

Each machine is different, and rotating equipment alignment methods will ultimately depend on your specific piece of rotating equipment. However, most of Cornerstone Mechanical’s laser alignment services involve these three key steps.

Step #1:

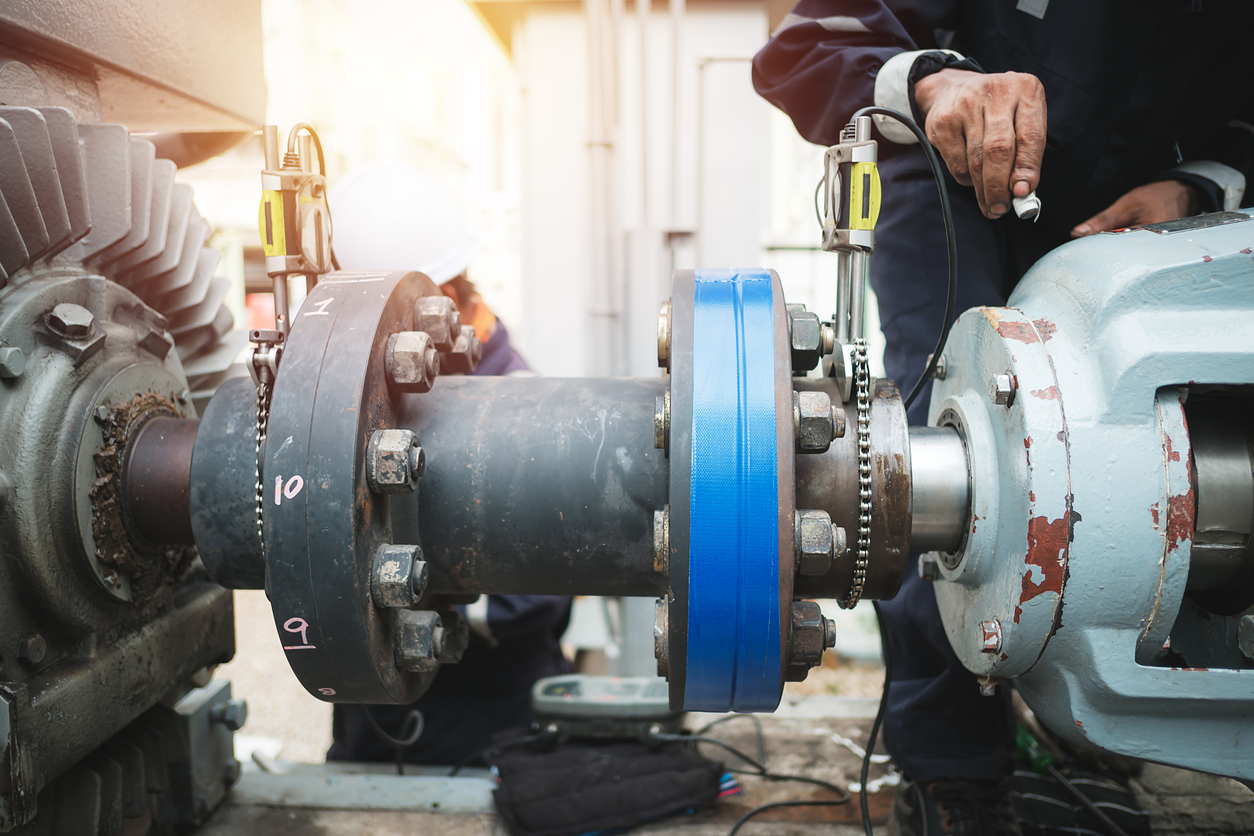

Our reliability technicians use alignment target values to determine both vertical and horizontal offset and angularity values. To determine these target values, our team laser aligns machinery “cold”, or while it’s turned off. Then, we start the machine, running it until it reaches operating temperatures.

Step #2:

Our team quickly sets up the laser and records the machinery’s “hot” alignment values. These are the measured shaft alignments of rotating equipment once it’s been running long enough to reach its standard operating temperature. Our reliability technicians may also measure “soft-foot”, or vertical, movement of your machine’s feet.

Step #3:

We realign your machinery while it’s running to account for thermal growth, document the alignment changes in a detailed laser alignment report and provide you with said report for your future reference.

Don’t tolerate your machinery’s abnormal vibrations or loud noises any longer.

Count on the Cornerstone Mechanical team to get your rotating equipment back up to snuff (and stay that way) with our comprehensive laser alignment services. Call us at 214-225-7038 to see how our laser alignment services can benefit your facility.