Table of Contents

- What is Corrective Maintenance?

- What is the Difference Between Preventive and Corrective Maintenance?

- What is the Difference Between Predictive and Corrective Maintenance?

- Why is Corrective Maintenance Important?

- How Cornerstone Does Corrective Maintenance Differently

Every second counts when a piece of rotating equipment fails. You’ve got deadlines to meet, production goals to reach and employees to protect. Simply put: you don’t have time for this. Corrective maintenance allows you to minimize downtime, reduce costly delays and keep your facility running smoothly, even when the unexpected happens.

But what does corrective maintenance entail, and how does it compare to other types of maintenance? As experts in a variety of maintenance services for rotating equipment, we’re here to answer these questions and more to help you make smarter decisions for your facility.

What is Corrective Maintenance?

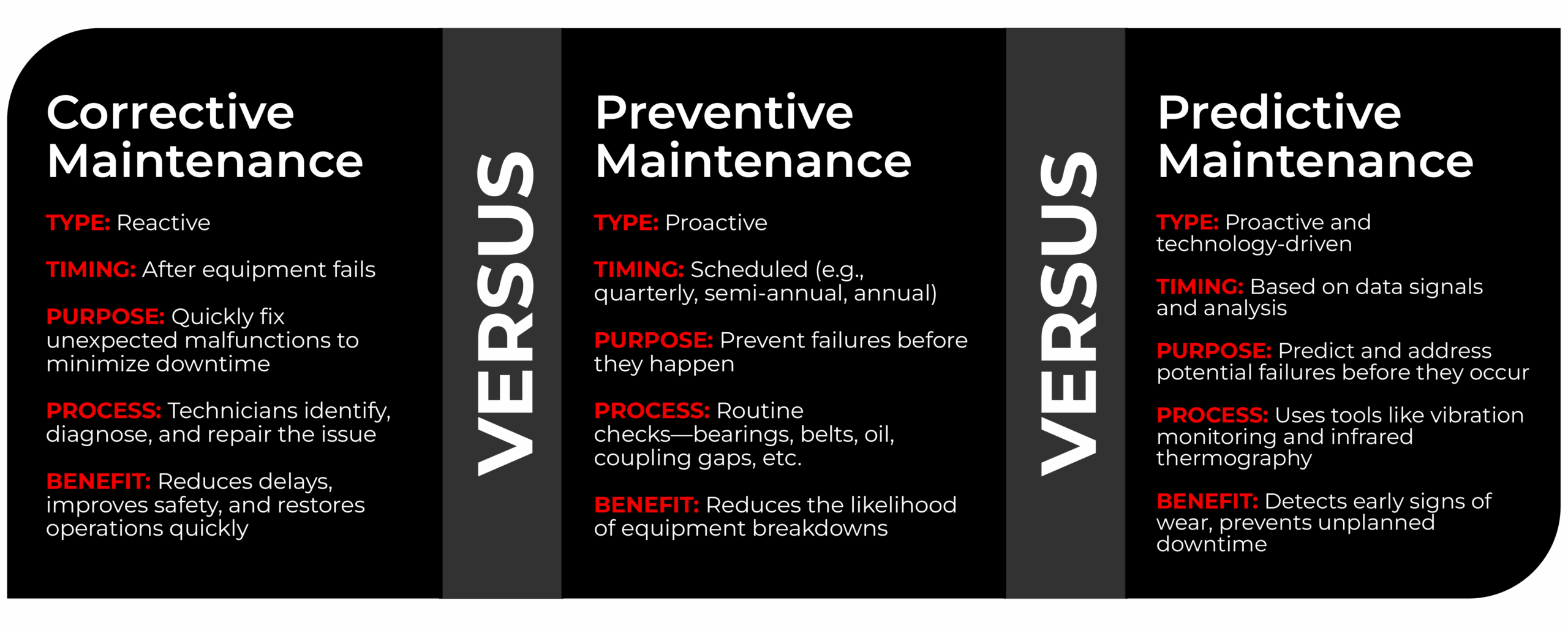

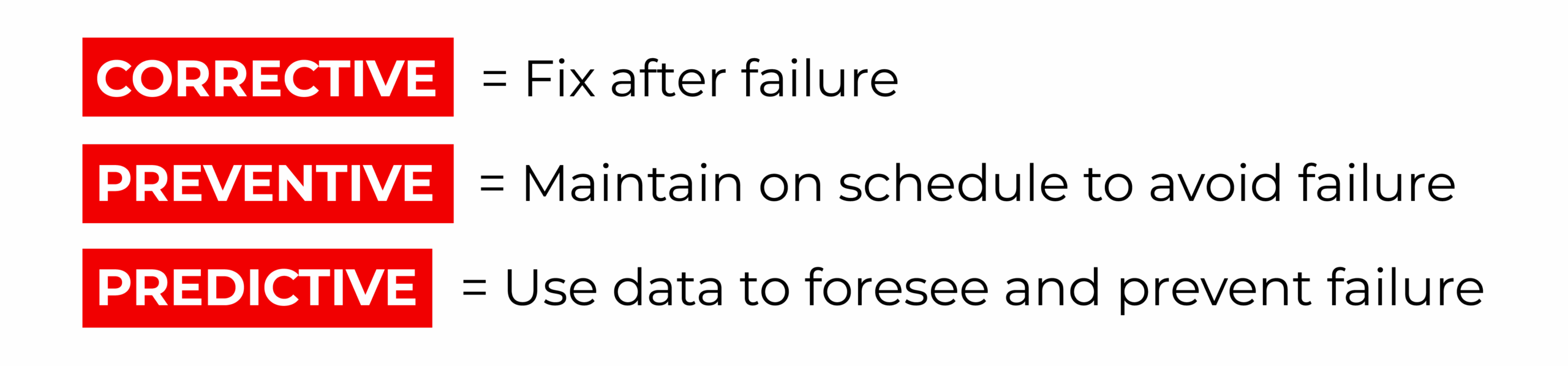

Corrective maintenance is unscheduled maintenance that occurs when pieces of rotating equipment malfunction unexpectedly and require immediate attention. It’s a reactive kind of maintenance as opposed to a proactive kind of maintenance. When performing corrective maintenance, reliability technicians identify, diagnose and solve the source of the failure to get your facility back up and running as quickly as possible.

What is the Difference Between Preventive and Corrective Maintenance?

While corrective maintenance occurs following an instance of equipment malfunction, preventive maintenance is regularly scheduled maintenance that aims to proactively prevent rotating equipment failure. Preventive maintenance may be performed on a quarterly, semi-annual or annual basis to assess bearings and coupling gaps, replace oil, tighten belts and check on any other rotating equipment components to make sure they’re all up to snuff. Corrective and preventive machine maintenance are relatively similar, but one is more proactive than the other.

What is the Difference Between Predictive and Corrective Maintenance?

Corrective maintenance reacts to equipment failures while predictive maintenance uses technology to predict when said failures may occur. Through vibration monitoring and analysis, infrared thermography and other services associated with a predictive maintenance program, reliability technicians are able to identify problem areas within components of rotating equipment long before they turn into a more serious issue and result in costly downtime.

Why is Corrective Maintenance Important?

When a piece of rotating equipment malfunctions, corrective equipment maintenance services allow you to get back to business as quickly as possible with minimal downtime. Through corrective maintenance, you can decrease the amount of production delays, missed deadlines and dissatisfied customers that may result from equipment failure. Corrective maintenance also extends the life of your rotating equipment and improves employee safety by quickly addressing minor issues before they turn into serious safety hazards.

How Cornerstone Does Corrective Maintenance Differently

When your rotating equipment experiences a malfunction, you need more than a quick fix. You need a trusted partner. At Cornerstone Mechanical, our highly skilled reliability technicians are known for their precision and efficiency in both diagnosing and solving problems associated with your rotating equipment.

As an ISNetworld-certified company, we built our safety culture and processes to protect people and equipment. Most importantly, as a company rooted in Christian values, we strive to serve our customers with integrity and care. If you’re not satisfied with any aspect of our services, we promise to make it right.

Our corrective maintenance services include, but aren’t limited to:

- Centrifugal pump repairs

- Exhaust fan repairs

- Bearing replacements

- Gearbox replacements

- And more

When your rotating equipment fails, time is money. The safety of your employees, the satisfaction of your customers and the efficiency of your facility’s production are all on the line. Whether you’re experiencing an unexpected malfunction or you’re looking for a long-term maintenance partner from Dallas/Fort Worth to Shreveport, and all the places in between, Cornerstone Mechanical is ready to serve you and get your facility back up and running with minimal downtime.

Call 214-225-7038 to learn how corrective maintenance services from Cornerstone Mechanical can help you get back to business.